******PLEASE NOTE*****

The technology of today’s waxes and polymers contain Nano particles that are designed to bead up water and make it dissipate from the surface. Decals will not stick to the window or surface if ANY residue from wax, rain-x other chemicals remain on the window.

Window or surface must be completely clean from these chemicals and wax’s before installation.

We recommend using a good rubbing alcohol to clean the window.

Decals by default go on the outside of the window.

DO NOT INSTALL on the inside if you have aftermarket window tinting, if you do and attempt to remove the decal you will destroy the aftermarket tint.

Decals can be installed on any hard smooth surface however decals installed on DPE plastics will fail in a short amount of time. DPE plastics such as ice coolers, toolboxes are designed to resist dirt, tar, adhesives etc.

Decals are measured at the longest side unless specifically noted in the listing, there may be a slight variance up to 1/2 inch on smaller decals to accommodate plotter restraints.

Color variations from screen to screen can happen and shade differences are normal. Vinyl is cut from solid color rolls of vinyl so special colors are not available.

Dry method Installation Video

Wet method installation video

Please note the wet method takes a lot of patience but can achieve a better result.

Video Courtesy of #handyharvey

Whatever method you choose, take your time and your decal will turn out great.

Written Instructions for dry method

Please install your decals as quickly as possible to prevent wrinkles that may occur in the shipping process.

If the decals sit for long periods of time without being installed it can make it extremely difficult to install, humidity and temperature fluctuations can prevent the decal from wanting to separate from the backing and or carrier papers.

Full Color decals should not be rubbed hard after removal of the installation tape it will fade the decal.

INSTALLATIONS FOR SMALL DECALS

Failure to follow these direction can cause damage to your decal and is not covered under replacement policy.

Surface temperatures should be between 50 and 90 degrees Fahrenheit before attempting the installation. As a general rule, if the surface is hot to the touch it’s over 90 degrees Fahrenheit. Adhesive becomes brittle when it gets too cold and gummy when it gets too hot. Applications outside the recommended range of 50 to 90 degrees Fahrenheit reduce the adhesives’ ability to perform.

Full color decals can not be rubbed hard after install or they will fade. please rub before removing installation tape.

- 1. Place decal on a hard smooth surface face up and rub over the decal with a credit card, squeegee or your thumb rub firmly with heavy pressure.

- 2. Clean surface thoroughly with alcohol then a clean dry cloth or paper towel.

- 3. Starting at a corner SLOWLY Peel off the backing AT A ANGLE away from the installation tape, IF ANY PART OF THE DECAL remains attached to the backing paper as you are peeling it away lay the tape back down on to the backing and firmly re-rub over the decal. If the backing paper tears and sticks to the decal, carefully peel the stuck backing paper away from the decal before installing. Once decal is removed from the backing paper move on to next step.

- 4. Place the decal on the glass or other smooth surface where you want it to stick, IT WILL STICK INSTANTLY.

- please make sure the decal is straight and aligned before sticking it to the surface. Decal can not be repositioned it sticks instantly. Do not use the backing or application tape as a measuring point it is cut by hand and may not always be perfectly aligned. Use the decal itself as your reference point when measuring.

- 5. Rub over the installation tape with a credit card, Squeegee or your thumb using heavy pressure working out any bubbles that may have formed while placing the decal on the surface.

- 6. Wait a minute or two to let the adhesive bond

- 7. Slowly peel off the installation tape pulling gently at a angle. (if the decal tries to stay attached to the installation tape lay the tape back down and apply heavy pressure using your thumb, a credit card or squeegee)

Window Decals are cut from sheets of sign vinyl and are not designed to be left for long periods of time without being installed. Please install as soon as possible to avoid issues during the installation.

******PLEASE NOTE***** . The technology of today’s wax’s and polymers contain Nano particles that are designed to bead up water and make it dissipate from the surface. Decals will not stick to the window or surface if ANY residue from wax or rain-x or other chemicals remain on the window. Wait a few days before washing the vehicle to allow time for a good bond. DO NOT POWER WASH

LARGE DECALS Body Side Graphics etc.

Large Decals and Graphics are recommended to be installed by a Professional for best results, they can be time consuming and require patience to install properly to get the decal straight and without air bubbles if you install yourself you can use the instructions below. We do not replace for failed installation.

Surface temperatures should be between 50 and 90 degrees Fahrenheit before attempting the installation. As a general rule, if the surface is hot to the touch it’s over 90 degrees Fahrenheit. Adhesive becomes brittle when it gets too cold and gummy when it gets too hot. Applications outside the recommended range of 50 to 90 degrees Fahrenheit reduce the adhesives’ ability to perform.

Fluting can occur in shipping due to different weather conditions and humidity. Before installation lay the decal on a hard smooth surface. Tape on end of the decal to the surface. Peel the decal and the application tape away from the backing starting at the non taped end. Then slowly lay the decal back down on the backing paper. This will remove any fluting from the decal and leave a completely flat decal ready to install.

- Please ensure the temperature of the decal and the installation surface is above 70 degrees, this will aid in the bonding process.

- 1. Place decal on a hard smooth surface face up and rub over the decal with a credit card, squeegee or your thumb rub firmly with heavy pressure.

- 2. Clean surface thoroughly with alcohol then a clean dry cloth or paper towel.

- 3. Starting at a corner SLOWLY Peel off the backing AT A ANGLE away from the installation tape, IF ANY PART OF THE DECAL remains attached to the backing paper as you are peeling it away lay the tape back down on to the backing and firmly re-rub over the decal. Once decal is removed from the backing paper move on to next step. If you still have issues lay the decal back down on a smooth surface and use a hair dryer on low setting to warm the vinyl, temperature and humidity play a role in the release of the vinyl from the backing TAKE YOUR TIME

- 4. Place the decal on the glass or other smooth surface where you want it to stick, be sure it is straight and level. Do not use the backing or application tape as a measuring point it is cut by hand and may not always be perfectly aligned. Use the decal itself as your reference point when measuring.,IT WILL STICK INSTANTLY

- 5. Rub over the installation tape with a credit card, Squeegee or your thumb using heavy pressure working out any bubbles that may have formed while placing the decal on the surface.

- 6. Wait a minute or two to let the adhesive bond

- 7. Slowly peel off the installation tape pulling gently at a angle. (if the decal tries to stay attached to the installation tape lay the tape back down and apply heavy pressure using your thumb, a credit card or squeegee) If you still have issues with the decal not adhering, use a hair dryer to warm the vinyl. Different temperatures and humidity levels in different regions can play a factor in the peeling of the installation tape.

Window Decals are cut from sheets of sign vinyl and are not designed to be left for long periods of time without being installed. Please install as soon as possible to avoid issues during the installation.

INSTALLATIONS FOR FULL COLOR DECALS

On full color decals use the same process however after installation tape has been removed, do not rub over the decal harshly the decal is printed on Weatherproof Vinyl with UV resistant ink. If you rub over the decal you may remove or scratch the ink embedded on the vinyl.

Windshield And Rear window Decal Installation Instructions

Failure to follow these direction can cause damage to your decal and is not covered under replacement policy.

Applying your custom vinyl graphic is easy enough to do by yourself. The following tools are

recommended when applying vinyl decals or lettering.

Masking tape

Level

Squeegee

Pin or exacto knife (optional)

Decals are not designed to be left rolled for long periods of time. Please install your decals as quickly as possible to prevent wrinkles that may occur in the shipping process.

Cleaning Procedure

All surfaces are contaminated to some degree. To ensure good adhesion to any vehicle surface it is critical that you follow

these recommended procedures in decontaminating and preparing the surface prior to any vinyl product installation.

1. Wash and rinse the area with liquid dish detergent and warm water. Then dry the vehicle surface with a clean, lint-free

towel or cloth.

2. Finish up the cleaning process by wiping down the entire area with Isopropyl Alcohol (rubbing alcohol). To avoid recontamination during the final cleaning step, wipe the surface in just one direction, using a clean, lint-free towel or cloth. You are now ready to apply the vinyl.

Temperature Recommendations:

Surface temperatures should be between 50 and 90 degrees Fahrenheit before attempting the installation. As a general rule, if the surface is hot to the touch it’s over 90 degrees Fahrenheit. Adhesive becomes brittle when it gets too cold and gummy when it gets too hot. Applications outside the recommended range of 50 to 90 degrees Fahrenheit reduce the adhesives’ ability to perform.

Application Procedures:

The base material is vinyl. Because vinyl is a pressure-sensitive product, direct pressure to the product is

very important. Please use your thumb or a soft, non-marring tool to apply pressure such as a squeegee or credit card.

Fluting or Tunneling can occur in shipping on rolled decals.

If your decal has fluting or tunneling ( ie pulling away from the backing and or curled, Follow the instructions below.

After removing the decal from the box and Prior to installation,

Lay the decal on a flat surface and tape one edge to the surface with masking tape or painters tape.

Starting on the opposite edge and at a corner Slowly peel the application tape up with the decal attached to it, leaving the wax backing behind on the surface.

Now use a squeegee or credit card to smooth the decal back down onto the wax backing. You have now removed the tunneling or curling from the decal.

Illustrated Installation Procedures

Step 1

After thoroughly cleaning the windshield surface, find and mark

it’s center with a small piece of tape or white grease pencil. Take

care not to use the Rear View Mirror mount for reference as not

all mirrors are placed at exact windshield center.

Step 2

Locate and mark center of the Windshield Decal. Center can

easily be found by folding the decal lengthwise in two . The

resulting crease is center.

Step 3

Once centers are found, place decal onto windshield so as to

become familiar with desired placement. Do not use the backing or application tape as a measuring point it is cut by hand and may not always be perfectly aligned. Use the decal itself as your reference point when measuring.

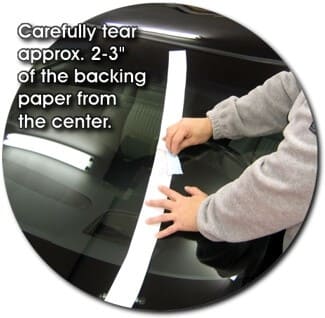

Step 4

Recommended method of installation is the Center Hinge. This

is achieved by carefully removing a 2-3″ portion of the backing

paper from the center as shown.

Step 5

Once a portion of the center is removed, simply fold back each

side of the backing paper approximately 1″ (25.4mm) onto itself.

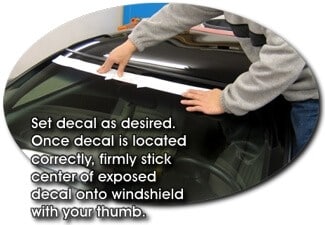

Step 6

Then, turn the decal over and carefully set it in the desired

location, making sure it’s centered. When placed correctly, stick

the center exposed area down with your thumb.

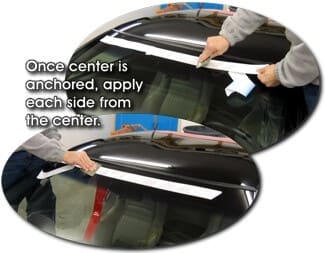

Step 7

Once “hinged”, apply each side of the decal from the center with

an application squeegee or soft non-marring tool.

Step 8

To remove the application tape, peel SLOWLY at a sharp (180°)

angle. If the vinyl appears to be lifting, gently push the

application tape in the opposite direction from which you were

pulling and re-squeegee that area. If after removing the

application tape, air bubbles are apparent, puncture the vinyl

with a pin or needle (DO NOT USE a knife or razor blade) and

squeegee out the air towards the puncture.

Exterior Graphic Care

Today’s finest pressure-sensitive vinyl materials have been used to create your new graphics. These graphics require little

maintenance and should be treated similarly to a painted surface.

Wash your graphics with plain soap and water or any commercially made car wash soap. Rinse thoroughly. Please wait a few days after installation to wash to insure a good bond.

Keep high pressure nozzles at least 18 inches from the edge of the graphics. High pressure spray may cause the edge of

the graphic to peel.

Test any cleaning solution on a small section of the decal before using. Be sure to read the solution’s directions and warning notices that may apply to Vinyl Graphics.

Don’t use any aromatic solvents such as acetone, M.E.K., toluene, paint thinner, or lacquer thinner on your graphics. Any solvent may soften the vinyl material or smear colors.

Don’t apply wax over graphics. Wax products generally contain petroleum distillates, which can damage vinyl graphics.

Note about Windshield Lettering Products: There is no warranty on windshield lettering products against peeling,

wiper blade damage, ice scraper damage, or any other type of damage that may occur. While these occurrences all prove to be out of our control, rest assured that the vinyl materials used are Premium grade with a life expectancy in regard to colorfastness of 5-7 years.

Wall Decals

Decals can not be re-positioned after installed they can be removed without damaging the wall or paint by simply using your finger nail to start peeling a corner and remove the decal.

**NOTE** Wall decals must be installed on a CLEAN SMOOTH WALL or the decal may not stick. Any residue from smoking or household grease from cooking will prevent the adhesion of the decal to the wall. Please ensure the wall is cleaned from any residue. No refunds or exchanges will be given on wall decals for failed installation.